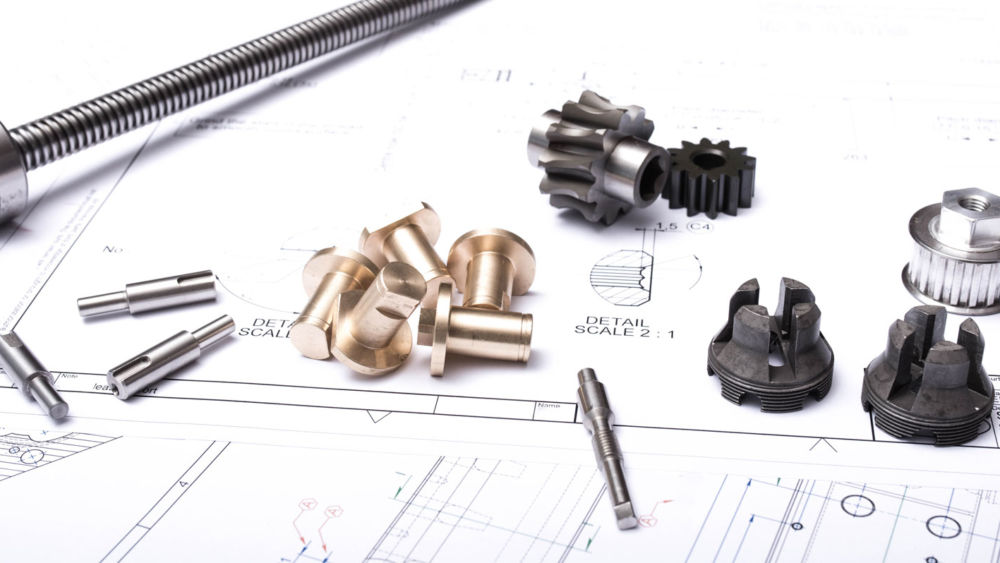

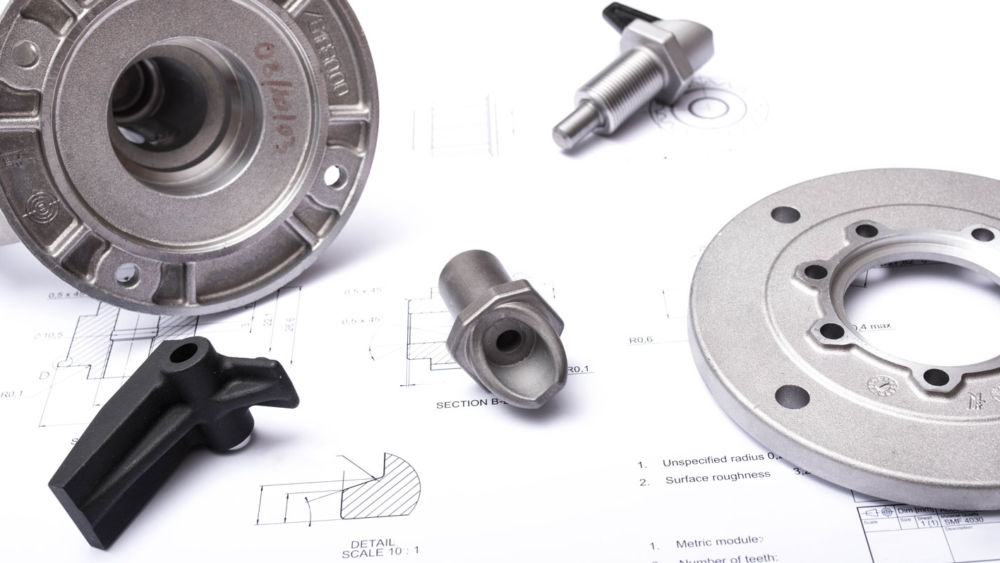

Component manufacturing

You are working on a new construction, and need new parts and components you have not worked with before. As we all do, you google and research online to find a number of different suppliers. But what component solution is the best and most cost-effective? Which of the suppliers should you choose? Who delivers with the exact quality and delivery reliability you expect? How do you solve the transport so that it will be best both temporal, economically and environmentally? And what is the best solution for your stock?

Rest assured. We at ESMA specialize in optimizing and customizing components and logistics solutions for the manufacturing industry.

Cutting processes is one of ESMA’s major areas of activity. The method can be used for the production of parts in most of the available materials, ranging from simpler components to high precision components with tight tolerances, in both small and large series.

Read more about cutting processes

Fasteners have been one of the foundations of ESMA’s business since the beginning in 1951, and it is still one of our biggest areas.

Read more about fasteners

ESMA collaborates closely with several different suppliers with various specialist skills in forging and pressing around the world.

Read more about forging & cold forming

With sintering, you can create complex components that get their final shape with little or no processing.

Read more about sintering & MIM

The casting process involves melting a material (usually a metal) into a mold to get a finished component.

Read more about casting

At ESMA, we work with a wide network of manufacturers, offering punched and bent components ranging from simple cutting tools to complex large stamping transfer tools.

Read more about punching, bending & springs

Plastics as construction materials have developed a lot in recent decades. Today, plastic can endure both extreme cold and heat without cracking or melting.

Read more about plastics

Vespel® is a high-performance polyimide from DuPont™, which is used in applications with friction, wear or high temperatures.

Read more about Vespel®

Polyurethane, PUR or PU, as it is also called, is a flexible material with properties that make it convenient to use almost everywhere.

Read more about Polyurethane

Step by step

How it works

Inquiry with drawing and volume -> Quotation

To ask for a quotation is always unconditionally, most often we only need a drawing and a volume before we can quote.

Manufacturing

We start production, monitor the delivery so the parts are on time and according to specification.

Logistic & safety stock

The parts are kept in our logistic center which enables flexible deliveries.

Packing & delivery

From general packing to customer specific instruction, packaging pools, EDI connections, Odette flags and more. We deliver just in time!

Deliveries to suit your systems

Logistics and warehousing is an ever increasing part of our business. ESMA can today offer our customers logistics solutions that include everything from using your own packaging and labeling tailored to your systems to document management in connection with import/export.